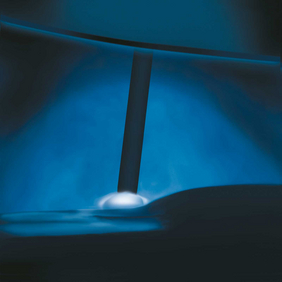

HAIGER – With Fine Weld CLOOS presents a new energy-reduced, current-controlled MIG/MAG short arc process for mixed gas and CO2 welding. Due to the minimised spatter formation, Fine Weld is suitable particularly for thin, coated plates and fine visible weld seams.

With Fine Weld, the lowest possible current flows in an arc phase before a drop short circuit occurs. When the liquid wire end comes into contact with the molten pool, a molten bridge should form as free as possible. For this purpose, the current is reduced even further for a short time. The short-circuit current which is then significantly increased to generate the pinch effect is very quickly reduced to low values again shortly before the short circuit is resolved, i.e. before the molten bridge is separated. As a result, the power in the newly ignited arc is kept low and the molten pool remains quieter due to the lower arc pressure. A short, uncritical current pulse afterwards ensures optimum drop formation at the end of the wire.

The stable arc is characterised by an optimum gap-bridging ability and can be mastered excellently in all welding positions. With Fine Weld, users reduce the workpiece distortion through the controllable heat input. The minimised spatter formation reduces extensive reworks and guarantees highest weld quality.

Download the QINEO StarT brochure:

Carl Cloos Schweisstechnik GmbH

Carl-Cloos-Strasse 1, 35708 Haiger

Stefanie Nüchtern-Baumhoff

Tel. +49 (0)2773 85-478

E-Mail: stefanie.nuechtern@cloos.de