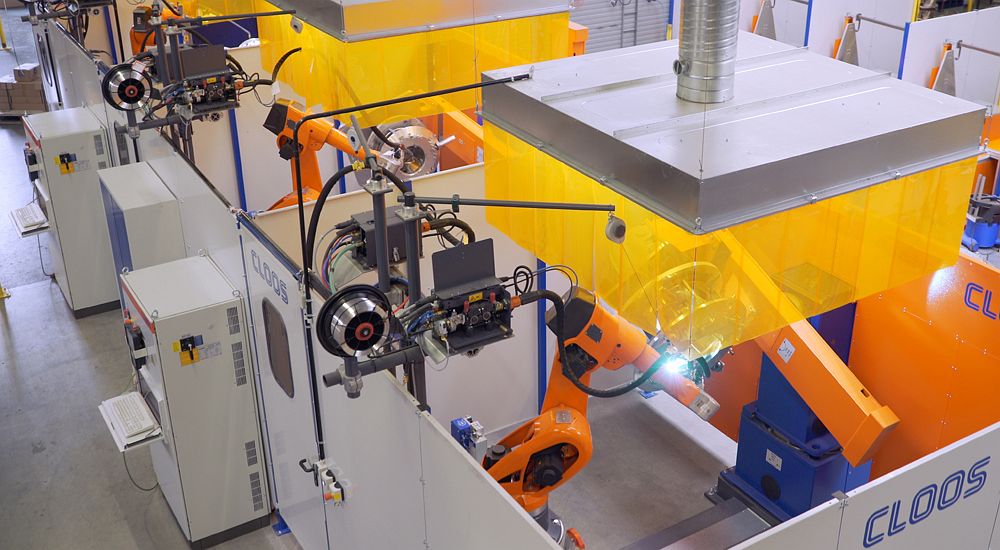

Interlinked robot system with intelligent shuttle solution at LTI Metalltechnik

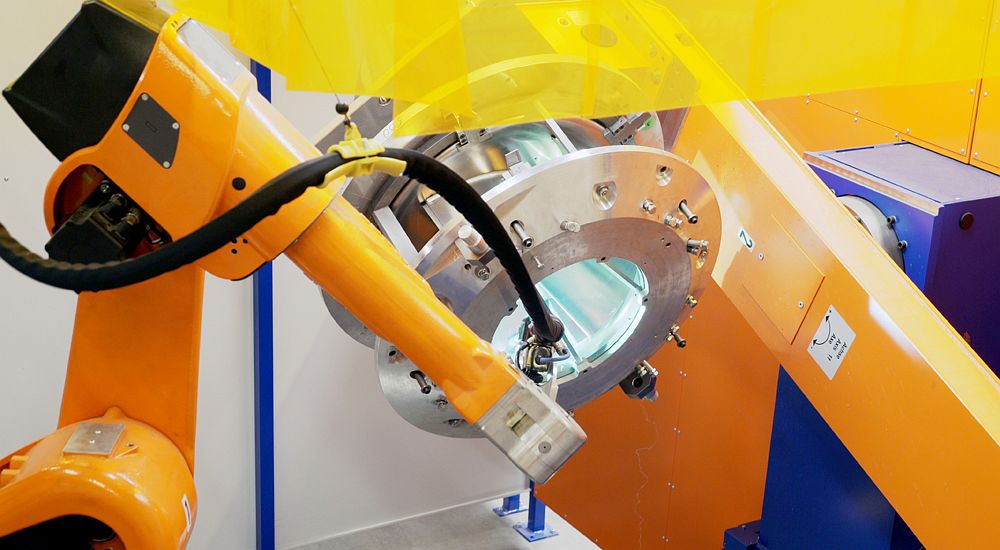

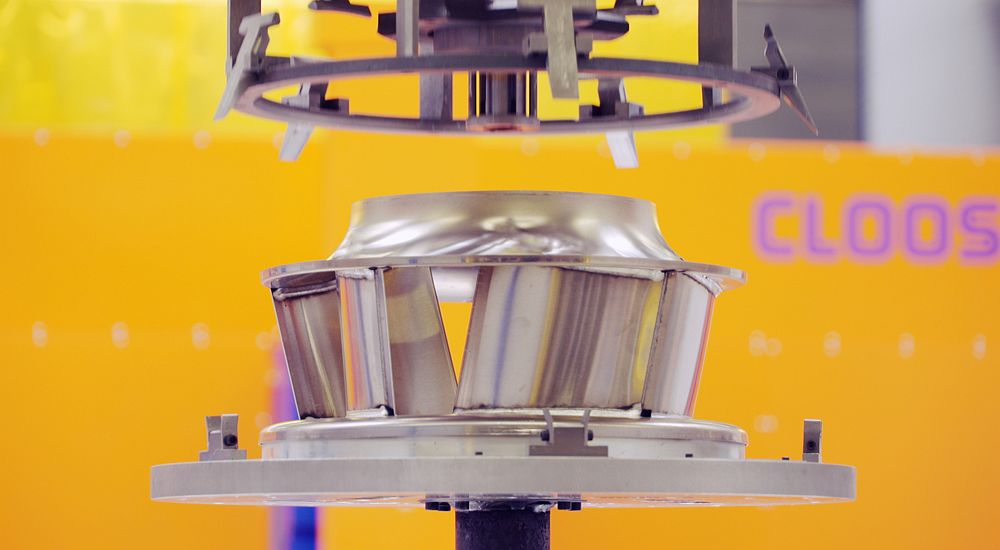

LTI Metalltechnik relies on an interlinked robot system from CLOOS for the welding production of ventilation wheels. The system has four loading and unloading stations and three identical welding stations. An intelligent shuttle system connects the individual stations with each other. A magnetic code on the fixture enables the shuttle in the loading area to recognize which welding station the component is being sent to. The three welding cells each have a workpiece positioner with a rotating and swivel movement that brings the component into the optimum welding position. The new robot system has enabled LTI to more than double the welding speed in the production of the fan wheels. The fully automatic handling also saves time. The robots also guarantee maximum process reliability.