CLOOS - Welding robots for efficiency and quality at Albert-Frankenthal

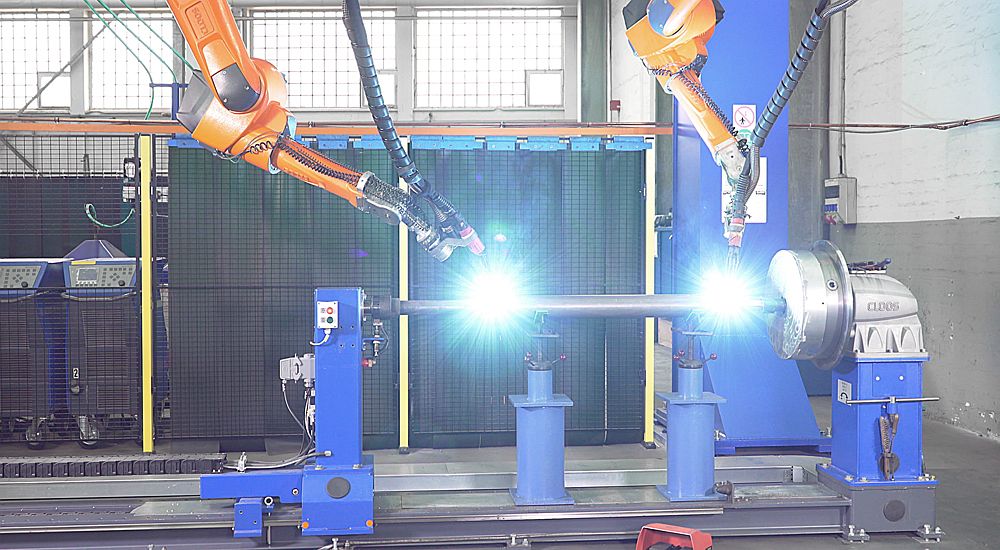

The CLOOS robot system consists of two stations: While the robots weld the workpiece on one station, the employee on the other side can remove the welded parts and reload the fixtures. The two QRC-350 welding robots are attached overhead to a vertical lift and can move flexibly back and forth between the two stations on a 12-meter-long gantry. This means that the robots can weld together at one station or in parallel at both stations, which increases the flexibility of the system enormously. Whether small batch sizes or larger series, the system can weld different types of rollers up to a workpiece length of 4.0 m. The welding robots are equipped with two welding torches: While the curved single-wire torch is suitable for welding short, jointed and difficult-to-access weld seams, the straight tandem torch can perform long straight weld seams at high speed.