QIROX RoboScan at Schwevers: efficient welding of small batch sizes - without programming effort

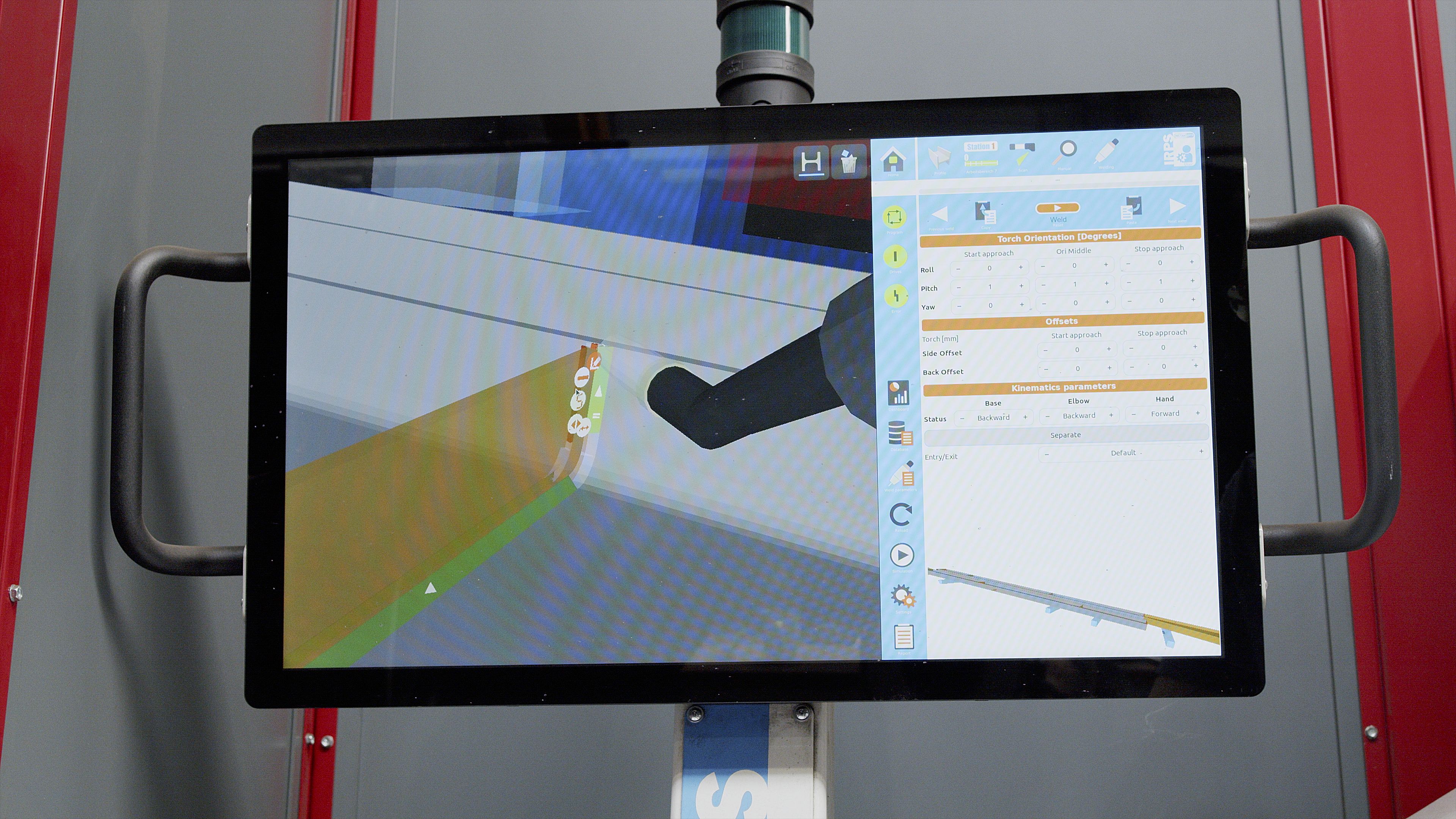

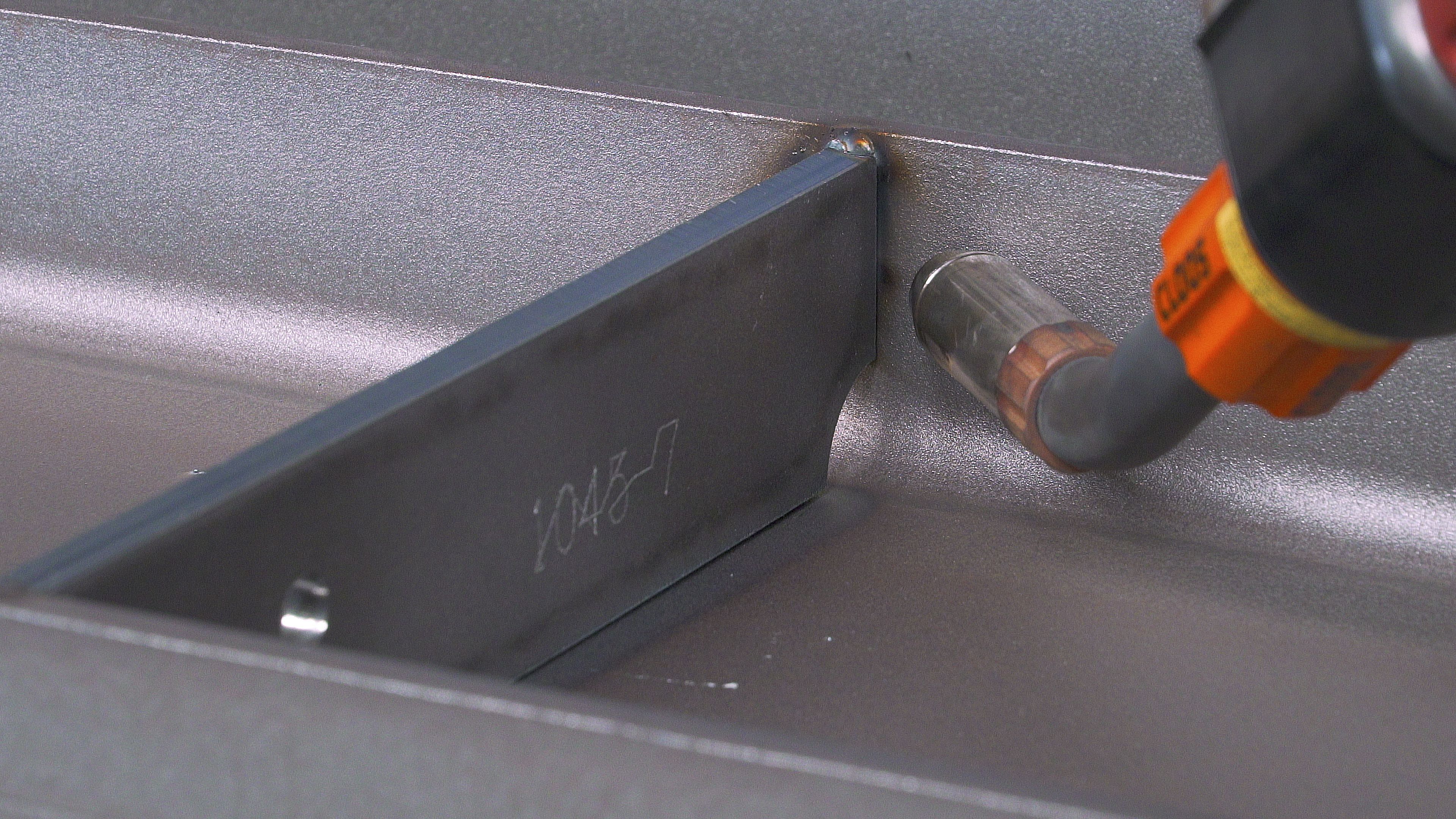

As a future-oriented partner for steel and building construction solutions, #Schwevers attaches great importance to innovative solutions in industrial and commercial construction. With the intelligent robot system from CLOOS, the company not only impressed its customers with the usual professional handling of projects, but also its employees. Thanks to the minimal programming effort and the simple operation of QIROX RoboScan, even workpieces in batch size 1 can now be welded automatically. The operator first positions the workpiece on the system's work station and the scanner, which is mounted on a longitudinal carriage, scans the work surface of the component and saves the result. The system recognizes weld seams such as fillet and corner seams as well as butt and lap seams and converts the stored data from the scanner into a 3D model, which appears on a screen. The welding program is automatically generated by comparing the 3D model with the component geometry stored in QIROX RoboScan. The operator can check the result and, for example, make corrections to the weld seam length or change the welding direction. QIROX RoboScan then transfers the fully generated program, including all welding data, to the robot controller and the welding process can be started simply by pressing a button on the QIROX RoboScan monitor.