Under the slogan "from prototype to small series", the SDFS Smarte Demonstrationsfabrik Siegen is expanding production for automated welding assemblies. Together with its technology partner Carl Cloos Schweisstechnik GmbH, SDFS realises production start-ups and small series for interested customers in a modern machine park as a manufacturing partner. With efficient manufacturing of customer-specific products, SDFS offers state-of-the-art, intelligent production in high quality.

Through the cooperation with the University of Siegen and the WZL machine tool laboratory of RWTH Aachen University, SDFS provides the link between science and industry. Young talents are actively promoted; students are thus given direct access to a real production environment to build up application-related skills. At SDFS, the latest research findings flow into production - for digitised and sustainable manufacturing.

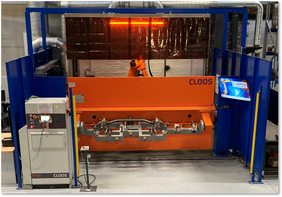

The SDFS offers near-series conditions for testing the readiness of its customers' products and processes for series production. They are fully supported in the production of prototypes through pre-series to series. This is made possible by the modern machinery at SDFS, consisting of a QIROX CS-40 compact welding system and manual welding power sources from technology partner CLOOS. Equipped with the 7-axis welding robot QIROX QRC-350-E and the Industry 4.0 interface C-Gate IoT Platform, the QIROX compact system is ideally suited for small series production. At SDFS, the focus is on digitisation: with the C-Gate IoT Platform, all process data can be centrally recorded and processed, with the system being monitored and evaluated. The system can be tailored to customer requirements and with features such as dashboards, intelligent evaluation options, mobile access, cloud applications and KPI evaluation, SDFS achieves state-of-the-art production together with CLOOS.

SDFS also has a solution for components that require machining in addition to welding. In cooperation with the partner company Achenbach Buschhütten, SDFS offers upstream or downstream drilling, milling and turning of the customer's own welded components.

The extensive experience of SDFS, CLOOS and Achenbach Buschhütten enables a fast and flexible implementation of the production order. For more information, please visit: https://demofabrik-siegen.de/produktion.

Contact

Fabian Steinberg, M.Sc.

Managing Director

E-Mail: f.steinberg@demofabrik-siegen.de

Mobile: +49 160 90338417

Carl Cloos Schweisstechnik GmbH

Carl-Cloos-Strasse 1, 35708 Haiger

Stefanie Nüchtern-Baumhoff

Tel. +49 (0)2773 85-478

E-Mail: stefanie.nuechtern@cloos.de