Many product innovations for manual and automated welding

HAIGER/HANNOVER – More than of 59,600 trade visitors came to visit the EuroBLECH 2014 from 21st to 25th October to find out about the latest technology trends for sheet metal processing. At the huge exhibition stand Carl Cloos Schweisstechnik GmbH showed their versatile processes and new solutions for manual and automated welding. "The exhibition was a great success for us. As the most important platform of the sheet metal working industry major industry trends are demonstrated here," summarised Gerald Mies, Managing Director of Robots and Welding Products at Cloos.

New generation of manual welding machines

The focus of the 200 m² exhibition booth was on the new product line of manual welding machines. In co-operation with Shenzhen Riland Industry CLOOS developed a completely new generation of inverter welding machines. A robust design, optimum ignition and welding characteristics and an excellent price/performance ratio are the main features of the Qintron. "Now our product range covers everything from the entry to the premium level and from simple manual machines to automated robot systems", says Mies. "With our high-tech products, we will also clearly stand out against the competition. At the same time, we want to grow and develop new markets", states Mies. The focus of the current product and future market offensive would be primarily on the BRIC countries (Brazil, Russia, India and China) and the MIST countries (Mexico, Indonesia, South Korea Turkey).

Automated solutions for all industries

In the automation range Cloos presented the new QRH-280 welding robot. This small, light and highly dynamic robot is perfectly suitable for the Cloos cell solutions. The compact design saves production area and guarantees a very good accessibility to fixtures. Thanks to the lower mass and smaller lever arm the robot achieves higher speed and thus a better positioning accuracy.

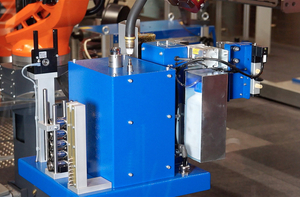

Another highlight was the fully automated current tip and gas nozzle changer SpareMatic which allows non-stop welding with operative components. When the welding robot needs new nozzles, the changer takes the torch consumables and replaces them by new parts. This process runs automatically and does not require an operator. Due to its compact, modular design, the SpareMatic can be integrated into both new and existing systems

Carl Cloos Schweisstechnik GmbH

Carl-Cloos-Strasse 1, 35708 Haiger

Stefanie Nüchtern-Baumhoff

Tel. +49 (0)2773 85-478

E-Mail: stefanie.nuechtern@cloos.de