![[Translate to English:]](/public/_processed_/9/9/csm_CLOOS_Schweisstec2019__1__web_6e5ee7b192.jpg)

[Translate to English:]

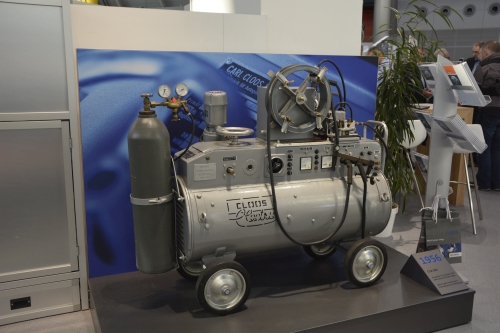

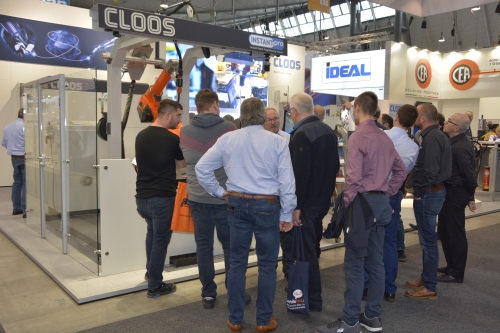

HAIGER/STUTTGART – At the trade fair duo of Blechexpo and Schweisstec from 5 to 8 November 2019 in Stuttgart, the visitors could inform themselves about all innovations of industrial sheet metal processing and cutting and joining technologies. This year, the theme of the exhibition booth of Carl Cloos Schweisstechnik GmbH was "100 Years CLOOS: Pioneers of Welding Technology" because the long-established company celebrated its 100 year anniversary. In hall 7, booth 7413 CLOOS presented innovative solutions future welding technology.

In Stuttgart, the visitors could expect a multitude of new products and innovations for a quicker, more economic and more flexible welding production. The welding specialists offer technologies from the entry to the premium level and from manual welding machines to automated robot systems from a single source.

Trade visitors could experience the wide QINEO welding machine range in live-demonstrations. The focus here was on the new QINEO NexT MAG. The high-tech MIG/MAG welding power source convinces by excellent arc characteristics for highest welding quality. The modular design allows many utilisation possibilities – from the basic welding machine for manual welding to the multiprocess welding machine for automated robot welding.

The right welding process for every application

CLOOS also showed new and proven welding processes for maximum productivity and quality. The new process family MoTion Weld for automated MIG/MAG welding is in the main focus. Due to the controllable heat input into the workpiece and the minimised spatter formation at high welding speeds, the MoTion Weld processes are particularly suitable for thin plate applications.

Besides, the welding specialists presented the possibilities of additive welding for the first time. Here a multitude of different components can be produced economically and resource-efficiently.

Industry 4.0 in welding technology

Another exhibition highlight was the new Gateway C-Gate by CLOOS. This enables demand-based management of welding and robot data. All information is entered and processed centrally in an integrated information and communication tool. The new system consists of the system-related hardware and different software modules. With the production module users can illustrate the performance and the efficiency of their robot systems, localise shortages and increase the efficiency.

Carl Cloos Schweisstechnik GmbH

Carl-Cloos-Strasse 1, 35708 Haiger

Stefanie Nüchtern-Baumhoff

Tel. +49 (0)2773 85-478

E-Mail: stefanie.nuechtern@cloos.de