HAIGER/BUCHLOE – For more than 20 years now, Rudolf Hörmann GmbH & Co. KG with head office in Buchloe (Bavaria, Germany) has placed its trust in welding technology by CLOOS. Last year the commercial and agricultural construction and power engineering specialists began operating two new CLOOS robot systems. This has enabled the company to considerably accelerate the production process for various components, whilst at the same time to increase quality and flexibility.

Rolf Hörmann GmbH & Co. KG has posted respectable growth. In the early years, the company specialised in the steel construction sector. This was joined over the years by agricultural & commercial building construction and photovoltaics. About two years ago, Hörmann also included mobile lightweight construction and industrial buildings into the product portfolio, offering users the highest levels of flexibility and mobility. "We support our customers from planning to the turnkey realisation of construction projects", explains Ewald Schunn, Production Manager for Metal Construction at Hörmann. The company now employs more than 600 people in Germany, Austria and Switzerland.

Successful collaboration

Trusting collaboration over decades binds Hörmann and CLOOS. "The key benefit with CLOOS is that they provide everything from a single source - starting with the robot, then positioner and now power source", Schunn highlights. PG Schweisstechnik in Kirchberg (Germany), CLOOS sales and service partner of many years, assumes the on-site support role.

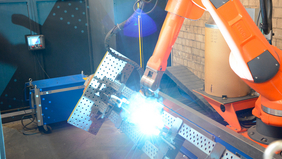

Hörmann now has more than 30 CLOOS welding machines in use in different production areas. The first robot system from CLOOS for automated welding entered operation at the company in 1989. It was joined by another robot system in 2007. Last year saw the 1990 system replaced by two new CLOOS systems. Now a QIROX compact cell and a QIROX "All in one" compact system assume the welding work of the diverse components. Recently, Hörmann also invested in a large, used robot system for the automated welding of semi-circular arches for mobile buildings.

"All in one" system with two welding stations

Hörmann is now welding mid-sized workpieces on the new QIROX "All in one" system. All relevant components are positioned on a joint base frame. They are fixed on a base plate so that a fine adjustment is not necessary. The heart of the system is the QIROX QRC-350-E welding robot. The large range of the seven-axis robot both simplifies and speeds up the welding of the partly complex workpieces. While the robot is welding the components on one side, loading or unloading is carried out simultaneously on the other station. The movable counter bearing can be used to adjust the clamping lengths within range 2.5 to 3 metres.

QIROX compact cell for small parts

The QIROX QR-CC-40 compact cell for welding smaller components has a 2-station workpiece positioner with vertical change and vertical rotation. By means of the rotary axis the station is turned from the loading area to the robot within 3 sec. During this procedure, the loading area is protected by a light barrier and an additional lateral safety fence There is a glare shield between the two stations. The system operator therefore has optimal protection and is able to load a station whilst welding is performed on the other station. All robot and positioner axes are fully synchronised. This provides excellent welding results, reduces the secondary processing times and speeds the entire process run enormously.

Carl Cloos Schweisstechnik GmbH

Carl-Cloos-Strasse 1, 35708 Haiger

Stefanie Nüchtern-Baumhoff

Tel. +49 (0)2773 85-478

E-Mail: stefanie.nuechtern@cloos.de