In the spring of 2015, the Czech specialist in solid fuel boiler production began operating two new "All in one" systems by CLOOS. Atmos now successfully operates a total of 15 welding robots supplied by Carl Cloos Schweisstechnik GmbH. The new series of compact robot systems combines high productivity with optimum efficiency.

The Czech family business Atmos is one of Europe's leading manufacturers of solid fuel boilers. Its product range includes wood, coal and pellet boilers as well as combined boilers for pellets, natural gas and oil. Atmos exports more than 80 per cent of its products abroad, mainly to Germany and other European countries. "Our products are characterised by an optimal price-performance ratio," explains Petr Antonín, Production Director at Atmos. "The demands our customers place on our products are high, so they expect the best quality and functionality."

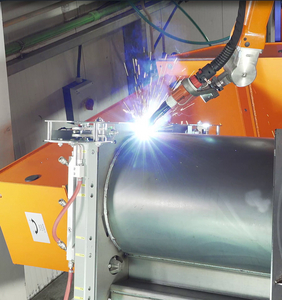

QIROX robots weld boilers

The two new robot systems are used to weld boilers and have significantly expanded the company's production capacity. The heart of the identical systems is the QIROX QRC-350 welding robot. The C-shaped frame with rotating extension arm positions the robot overhead. This increases the working envelope of the robot and facilitates welding of the complex boilers. The workpiece positioner with turning andswivelling movement and vertical stroke always brings the workpieces into the perfect welding position.

Carl Cloos Schweisstechnik GmbH

Carl-Cloos-Strasse 1, 35708 Haiger

Stefanie Nüchtern-Baumhoff

Tel. +49 (0)2773 85-478

E-Mail: stefanie.nuechtern@cloos.de