"Individual complete solution"

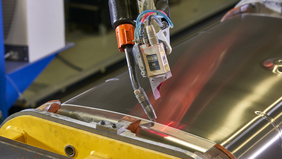

Haiger/Bursa – The Turkish company AKP Otomotiv relies on “Made in Germany” quality when welding aluminium tanks for HGVs. The two-station robot machine of Carl Cloos Schweisstechnik GmbH – fitted with the most modern welding technology – guarantees optimum welding results and maximum efficiency.

AKP Otomotiv has specialised in delivering parts for commercial vehicles and the automotive industry. The owner-operated family company, with its head offices in Bursa, is benefitting significantly from the economic upturn in Turkey over the last few years. Since it was founded in 1976, AKP has grown continuously and currently employs more than 200 staff. “Our principal clients include manufacturers such as Mercedes and Ford who wish to expand their production in Turkey over the next few years“, explains Ugur Caglar Memis, Operations Manager at AKP.

Aluminium as a Special Challenge in Welding

Lightweight construction is becoming ever more important even for commercial vehicles. For that reason, AKP uses an increasing number of parts made from aluminium. But the material represents a particular challenge for the welding process, as it is very sensitive. Since 2012 AKP has been welding aluminium tanks on the Cloos robot system. “One of our clients recommended Cloos as a competent partner for welding aluminium“ explains Memis.

Maximum Efficiency with Two-Station Operation

More than 60 aluminium tanks are welded daily on the Cloos robot system. A set-up with two stations results in an enormous saving in time in the process, as the machine can be loaded mutually. Whilst the robot at one station welds the workpiece, the person on the other side removes the welded tank and loads the devices again.

The workpiece positioner device with an adjustable counter-bearing enables automatic assembly of the tank shell with the top and the base. This removes the complicated pre-lifting of the individual tank workpieces. The two components of the workpiece positioner are mounted on a joint base frame. The counter bearing can be moved in an automated way on the base frame. This allows the gap between the two face plates to be fitted in a flexible manner for different tank sizes.

Carl Cloos Schweisstechnik GmbH

Carl-Cloos-Strasse 1, 35708 Haiger

Stefanie Nüchtern-Baumhoff

Tel. +49 (0)2773 85-478

E-Mail: stefanie.nuechtern@cloos.de